Get a free quote for your project. Click here.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

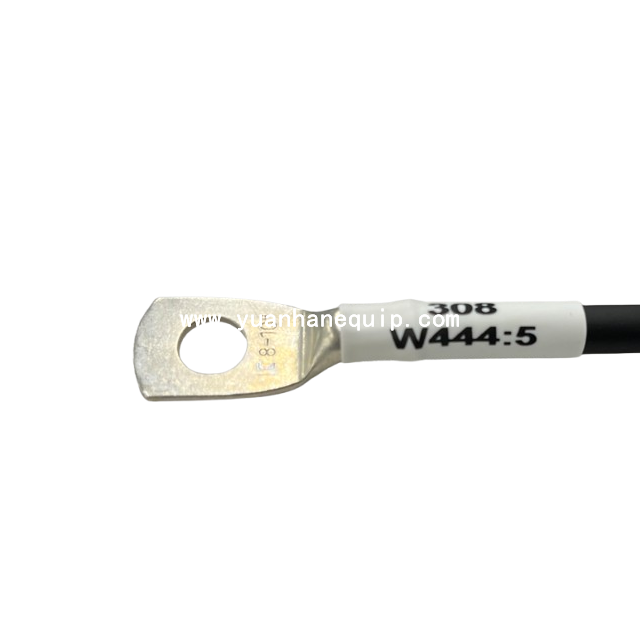

Our wire heat shrink tube laser printing inserting and shrinking machine is a cutting-edge solution for efficiently labeling and protecting wires in various applications. This advanced machine is designed to streamline the process of laser printing heat shrink tubes, inserting them onto wires, and shrinking them to provide a secure and durable labeling solution.

|

Model:

|

|

|

Brand:

|

|

○ Industrial automation PLC and industrial control all-in-one machine cooperate with upper computer software for control, featuring simple operation, stable work, and high efficiency.

○ Automatic printing of heat - shrinkable tube labels is realized through upper computer software, and characters can be set freely. At the same time, two different labels can be printed. The heat - shrinkable tube is automatically loaded and cut. The baking length is freely set with the fixture, and the position of the baking position is adjusted through the positioning device.

○ The production capacity can reach 1000 - 2000 terminals per hour (depending on the manual loading speed).

○ The equipment has strong compatibility, and can process various specifications of wire materials by replacing fixtures.

○ All series are equipped with a manipulator automatic wire taking device as standard. (It is selected according to standard wire materials and does not include automatic wire taking for special wire materials.)

○ For the printer, we adopt laser light source printing technology. The printed font is clear, waterproof and oil - proof, and it has a self - contained memory function. It also supports Excel table import for printing files, serial number printing and combined document printing, etc.

○ Laser printing does not need to use consumables, and it can print heat - shrinkable tubes of various colors (white, red, blue, etc.), meeting more process requirements. At the same time, when the laser is turned off, we can process conventional black heat - shrinkable tubes, which are compatible with all functions of standard models and fixtures.

○ Digital adjustment of temperature control and abnormal monitoring of heating devices. When the air pressure is too low, the heating device is automatically protected to prolong the service life.

○ To prevent operators from making mistakes in adjusting process parameters, the system can be restored with one key.

|

Model |

YH-DMRS500ST |

|

Input Voltage |

220V - AC |

|

Frequency |

50/60HZ |

|

Rated Power |

2500W |

|

Display |

7 - inch multi - point capacitive screen |

|

Equipment Operation Cycle |

2.5 seconds |

|

Operation Mode |

Passive |

|

System Control Mode |

PLC/Industrial Control Integrated Machine/Upper Computer Software |

|

Equipment Sleeve Compatibility Range |

Φ2.0/Φ10 Standard |

|

Equipment Sleeve Baking Length |

8MM - 45MM (fixture optional) |

|

Baking Temperature |

0°C - 400°C (adjusted by temperature controller) |

|

Air Pressure Requirement |

0.5/0.65MPa |

|

Operating Temperature |

0°C - 50°C |

|

Storage Temperature |

- 20°C - 60°C |

|

Operating Humidity |

10%RH - 90%RH (no condensation) |

|

Anti - interference Ability |

Interference voltage: 1500Vp - p, Pulse period: 1us, Duration: 1 minute |

|

Air |

No corrosive gas |

|

Cooling Method |

Forced water cooling |

|

Overall Dimensions |

Length 900 x Width 550 x Height 1290 |

|

Overall Machine Quality |

165KG |