Get a free quote for your project. Click here.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

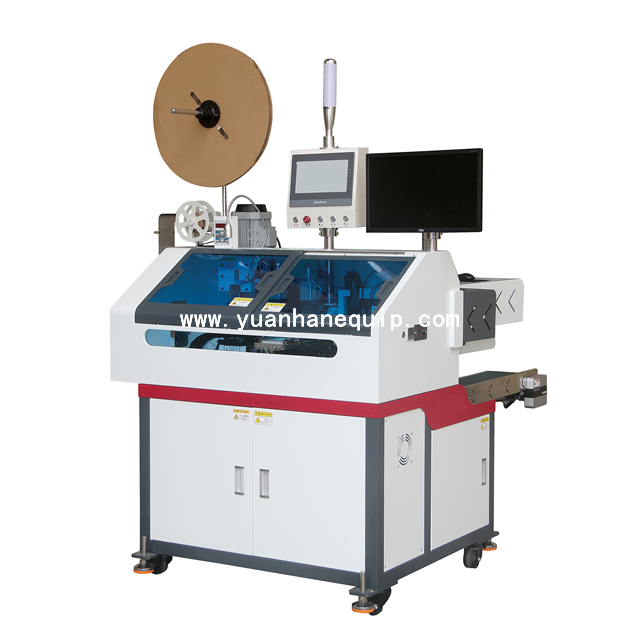

Our cable single end crimping and housing inserting machine is designed to revolutionize your cable assembly processes. With its cutting-edge technology and precision engineering, this machine offers unparalleled efficiency and accuracy.

|

Model:

|

|

|

Brand:

|

|

○ Crimping Excellence: Our machine ensures flawless crimping of cable ends, guaranteeing secure and reliable connections. The advanced crimping mechanism delivers consistent results, eliminating the risk of faulty connections.

○ Seamless Housing Insertion: With our machine's innovative housing insertion system, you can effortlessly insert connectors into cable housings. This process is streamlined and error-free, saving you valuable time and effort.

○ Versatility and Adaptability: Our machine is compatible with a wide range of cable sizes and connector types, making it suitable for various applications. Its adaptability allows for seamless integration into your existing production line.

○ User-Friendly Interface: The machine's intuitive interface simplifies operation, ensuring ease of use for operators of all skill levels. The clear display provides real-time feedback, allowing for quick adjustments and minimizing downtime.

○ Robust Construction: Crafted from high-quality materials, our machine is built to withstand rigorous industrial environments. Its durability ensures long-lasting performance, reducing maintenance costs and maximizing productivity.

○ Safety First: We prioritize the safety of your operators. Our machine is equipped with comprehensive safety features, including emergency stop buttons and protective guards, ensuring a secure working environment.

○ Enhanced Efficiency: By automating the crimping and housing insertion processes, our machine significantly increases productivity. It eliminates human error, reduces labor costs, and optimizes your overall production output.

| Model | YH-SHCJK02 |

| Power supply | AC 220V |

| Standard functions | wire cutting, single-end stripping, single-end crimping, single-end housing shell inserting; rear-end twisting, tin dipping |

| Optional features | CFM, wire stranding |

| Detection functions | presence of wires, knotted wires, presence of terminals, presence of plastic shells, air pressure alarm, motor abnormality, CCD visual inspection, tin shortage alarm, liquid level detection, etc. |

| Production capacity | 400-450 action cycles/hour (24 terminals/action cycle) |

| Cutting length | 30mm-750mm (Special specifications can be customized) |

| Cutting accuracy | +0.1mm + cutting length x 0.1% or less |

| Applicable connector housing spacing | 1.0, 1.25, 1.5, 2.0, 2.54, 3.96 (mm) |

| Processable wire range | AWG#32-AWG#18 (electronic wires and flat cables |

| Rear stripping length | 1-9mm (half-stripping or full-stripping, special specifications can be customized) |

| Tin dipping length | 1-9mm (special specifications can be customized) |

| Crimping machine | 2T variable frequency crimping machine |

| Air pressure | 0.6-0.7MPa (need clean and dry air) |

| Dimensions | L1900MM x W1100MM x H17 60MM |

| Weight | about 620KG |