Get a free quote for your project. Click here.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

Kunshan Yuanhan Electronic Equipment Co., Ltd.

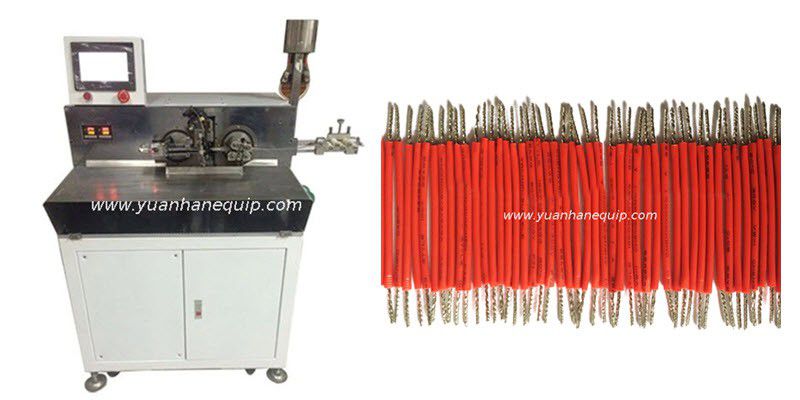

The multiple wires stripping twisting and tinning machine can process up to 10 lines at the same time. Main function: single or double ends cutting, full stripping/half stripping, tinning, and twisting.

Model: YH-06W

Features

Function: single or double ends cutting, full stripping/half stripping, tinning, twisting

Applicable wire size: 0.3mm - 3.0mm (AWG34 # - AWG16 #)

Roller feed line, length can be adjusted freely

All electric and pneumatic parts of the machine adopt Japanese SMC and Omron digital display air pressure and temperature control devices, sensing devices, etc., to make the whole machine operate more accurately.

90 ° tin dipping, tinning and twisting effect is even, and the dip depth is controlled by stepping motor, which is light, fast, accurate and high performance.

Using suction and blowing devices to deal with tin residue and cutting waste, clean and tidy.

Contact us: sales@yuanhanequip.com

Operation video of the Fully Automatic Wire Stripping Twisting and Tinning Machine

Technical Data

| Model | YH-06W |

| Source | AC 220V / 50/60hz single phase |

| Function | Single or double ends cutting, full stripping/half stripping, tinning, twisting |

| Productivity | Frequency: 2,000 times/time |

| Walking line | 10 lines (according to product specifications) |

| Capacity | 20K/hour (according to the product specifications) |

| Applicable wire size | 0.3mm - 3.0mm (AWG34 # - AWG16 #) |

| Cutting length | 8mm - 1,000mm |

| Stripping length | 0.1 mm - 10.0 mm |

| Torsion length | 3.0mm - 10.0mm |

| Tin length | 0.1mm - 10.0 mm |

| Air pressure | 7kgf (clean and dry air should be used) |

| Dimension | 600mm * 800mm * 1,100mm |

| Weight | 280KG |